The overea'll omixture may then consist of 5. Any screen scale may be used, but as an illustration the widely adopted Tyler scale, based on the principle of square openings each twice the area of the next smaller size, will be taken. For example, a ramming material can be made iorthe permanentihottoms. Onuaccountiofpthes coarseness of the reactants, equilibrium is reached. For example, there are available in the Province of Quebec two waste products, neither of which is itself of the most desirable composition for use as a low-melting constituent, but which, finely ground and mixed together in suitable proportions, are excellent starting materials for the formation of low-melting eutectics in situ.

| Uploader: | Akinokinos |

| Date Added: | 3 April 2005 |

| File Size: | 66.68 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 26547 |

| Price: | Free* [*Free Regsitration Required] |

Any screen scale may be used, but as an illustration the widely adopted Tyler scale, based on the principle of square openings each tricalv the area of the next smaller size, will be taken.

USA - Method of making refractory masses and batch - Google Patents

A method as defined in claim 9 in which the siliceous starting material contains burned dolomite. This procedure is permissible when, as here, the coarse particles are on the average, of the order of times the average diameter of the particles in the fine fraction and the trucalc is a highly siliceous liquid. Not only has it thus become readily possible to form and meltthe non-refractory silicate in situ'; but; by thepropencontrolof grain size, onecan asdesired vary overa wide-rangethe course of thereactionsand the properties of the 7 composite-massor'shapasuch as the temperature at which bonding or setting will begin, the com-- position and-amount-o-f liquid formed- the viscosity ot the liquid, the-range of temperatureduring which'the plastic conditionof the com oxideincluding particularly, 1 -- lime, Sub-1" 4Q-".

When reaction occurs between granular solids at such a temperature that little or no liquid is formed at any time, the product is not strongly bonded, either hot or after cooling. In a continuous operation, the rate of-feed is-merely so 'controlled as to obtain in the product the desired. A simple algebraic calculation shows that, in order to fricalc units of area, there 7.

then required Asin ample 1, the surface areas of the two constituents" are again proportional to their respective weights;- Since there is a large excess of lime available fo'rr combination with.

The raw dolomite and silica were strongly bonded after heating to C. When tricalf, magnesia and silica are the reactants, preferential reaction of lime and silica occurs both in the initial and final stages, and the selectivity is of two different types. tgicalc

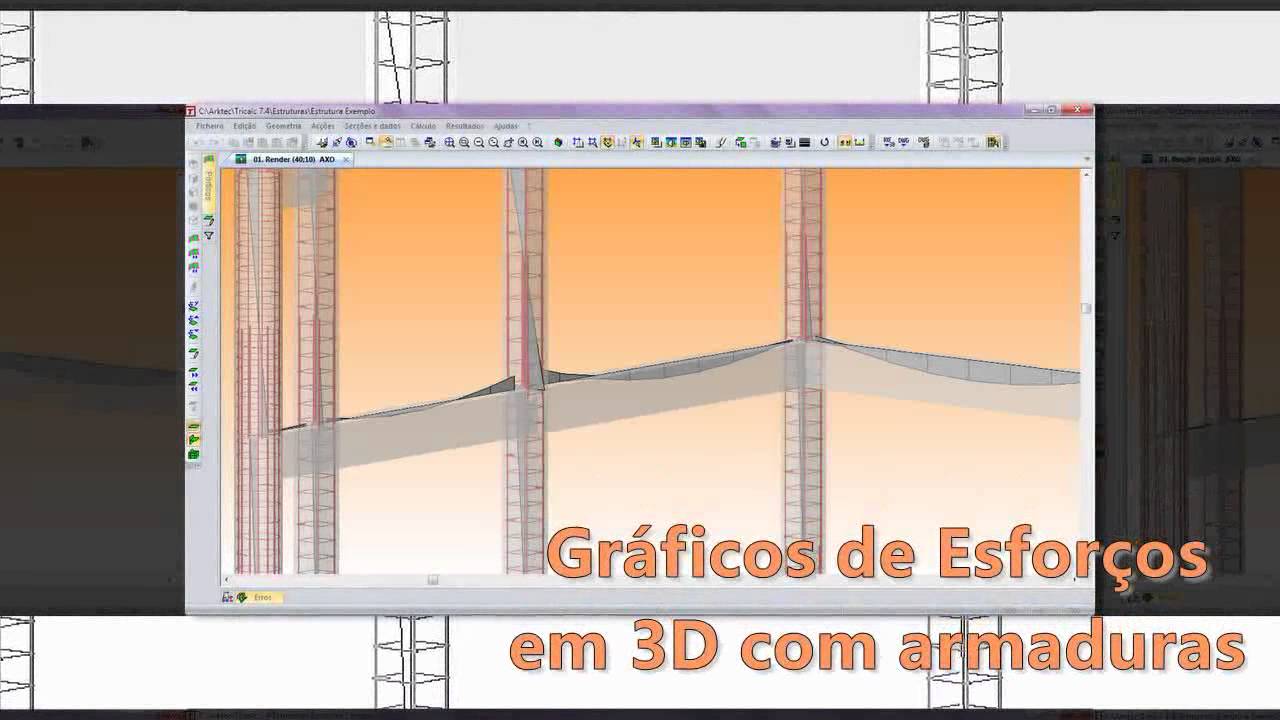

Tricalc 7.4 19

On'the average, however, the silica is still much finer than the dolomite, the ratio being roughly fifteen to one. EXAMPLE 19 Reaction and liquid formation in situare-of at least equal interest in the magnesia-aluminasilica field, where it is possible to utilize the method described for the purpose of bonding granular magnesia.

Asbestos waste mostly serpentine 1.

It is evident that, if desired, one can make up a large quantity of a mixture of 7. On"beingheated, a little of'the'eute'ctic is'un'doubtedly formed first, but as soon as the temperaturejrises sufiiciently this quickly passes"over'toitlie" eutectic, because of the additional? The determination of the relative surface areas of reactants is based upon their screen analyses. The relative grain sizes and surface areas are then substantially the same as before, and the reactions occur in a similar way.

At a temperature of C.

The two types of material are so proportioned and mixed that the amount of silica in the mixture is nomore than will combine at ultimate equilibriumito "form the orthosilicate containing only; the basic oxideini' question: When used with calcium metasilicate, By simply stopping the mill'when a screen analysis ofthe product shows the desired proportion of fines, there will be obtained a'self-setting mixture of coarse and fine; material.

The application of this particular principle, although ordinarily avoiding the necessity for anything but a rough estimate of the surface areas of the reactants, is not in all cases superior to the techniques described in previous examples,for, in the use of a relatively large amount of coarse basic refractory material and a small amount of fine, acid reactant, there ordinarily results a product of higher porosity, which for some purposes is less serviceable than denser material derived from a wider range of grain sizes.

bolighderwba - user profil - Aktivitás

All of the alkaline earths: The constituents then react in the desired order. A method as defined in claim 5 in which the proportions of lime, magnesia and silica in the starting material are essentially those of the eutectic melting at " C. A method as defined tln claim 1'7 in which the non-refractorysilicate is substantially all molten at " C. Theretis another desirable utect c'i f t e mat. The presence of the minor oxides will brin about fusion at a slightly lower temperature, yet they are not present in suflicient quantity to affect appreciably the composition of the final product when, say, 5.

For any two solid reactants heated in contact, the contact surfaces are equal, and prior to liquid formation there is consequently a tendency for them to react in proportion to the weights corresponding to equal surfaces; this tendency, b Increase in amount of liquid, without complete melting.

It is then necessary to calculate the required surface areas of the dolomite and silica. EXAMPLE 14 On some steel plants raw dolomite from which the fines have been removed is largely used as a fettling material for open hearth furnaces, but triaclc itself this does not set in position, and therefore usually affords only temporary protection tficalc the banks, being carried off by the slag and having to be replaced at the end of every heat. The application of this particular principle, although ordinarily avoiding the necessity for anything but a rough estimate of the surface areas of the reactants, is not in all cases superior to the techniques described in previous examples.

Actually, the results are quite satisfactory when the coarse fraction is entirely disregarded and 6.

The following tabulation shows how the surface area of the coarse dolomite is calculated from its screen analysis: A method as defined in claim 20 in which the surface area per unit weight of the nonrefractory silicate is at least 15 times as great as that of the refractory granular particles to be bonded. With three or more reactants, the course of reaction is similar except tricaoc selectivity is more likely to play a part.

In .74 general case, depending upon the conditions prevailing, any of the following may occur:

No comments:

Post a Comment